- The Scientific Frontier of Mokume Gane

- 1. Ian Ferguson’s Application of “Vacuum Solid-State Bonding” Techniques

- 2. “Bonding Optimization of Decorative Structures” by S. Atre & R. Kumar

- 3. Friction Stir Welding (FSW) as a New Lamination Method — Sheffield Hallam University

- 4. Nanostructure Analysis of Bonding Interfaces Using SEM and XPS — Wu & Yamaguchi

- 5. Reproducing Mokume Patterns via 3D Printing (SLM) and CAD — Schmidt et al.

- 6. Challenges and Future Directions — Toward Hybrid Methodologies

- Conclusion

The Scientific Frontier of Mokume Gane

Introduction

Mokume Gane, while rooted in traditional craft, has also emerged as a subject of active research in materials engineering and manufacturing science. This article introduces recent scientific papers that investigate Mokume Gane from an engineering and materials science perspective, highlighting its integration with modern technologies.

1. Ian Ferguson’s Application of “Vacuum Solid-State Bonding” Techniques

Research Overview:

Ian Ferguson (RMIT University) applied vacuum diffusion bonding, a method commonly used in aerospace engineering, to Mokume Gane, developing a technique for fabricating large-scale billets.

Key Points:

- Enables bonding at relatively low temperatures (~600 °C)

- Demonstrated success with over 40 different metal combinations

- Repeatable bonding process using modern furnaces and pressure equipment

Engineering Significance:

This approach provides a foundation for transforming Mokume Gane from a “craft reliant on intuition” into a reproducible, controllable manufacturing process.

2. “Bonding Optimization of Decorative Structures” by S. Atre & R. Kumar

Paper:

Diffusion Bonding of Dissimilar Metal Laminates in Decorative Mokume Gane Structures (2009, Journal of Materials Processing Technology)

Overview:

- Thermodynamic calculations and bonding trials using dissimilar metal stacks (Ag–Cu–Au)

- Evaluation of delamination and interlayer separation under various bonding temperatures, times, and pressures

- Suggested conditions: 750–850 °C, specific pressure, ~30 min hold time

Significance:

Provides scientific guidelines to optimize bonding parameters for both strong adhesion and beautiful pattern formation.

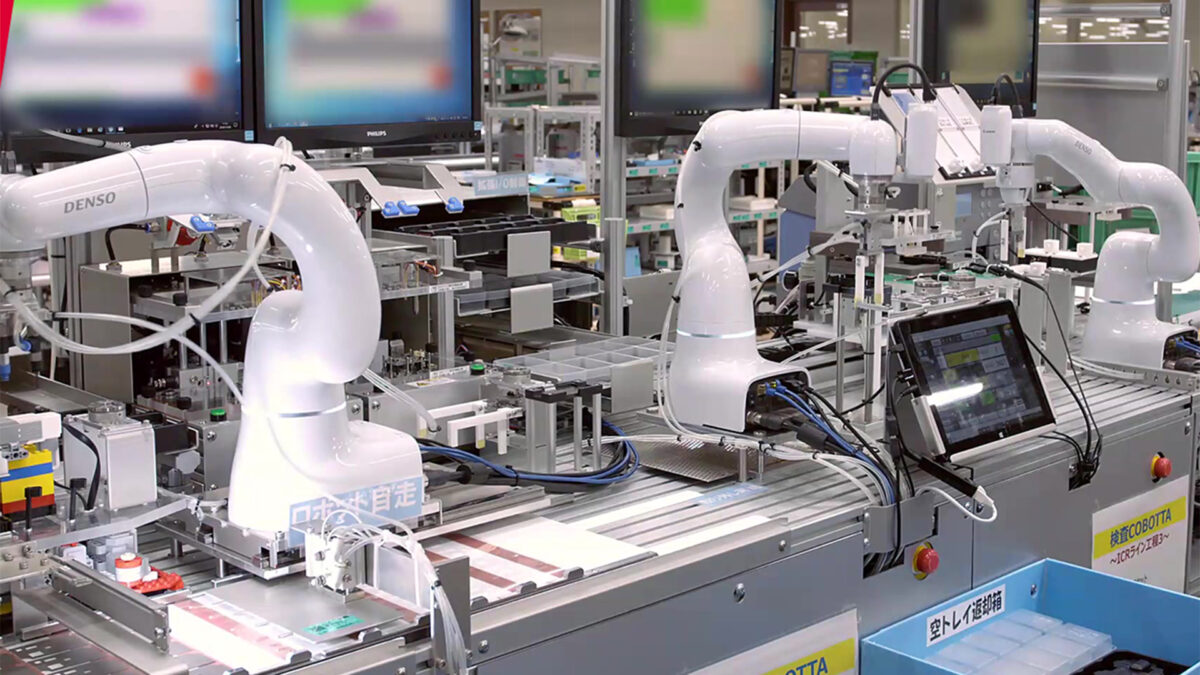

3. Friction Stir Welding (FSW) as a New Lamination Method — Sheffield Hallam University

Paper:

The Use of Friction Stir Welding for the Production of Mokume Gane-Type Materials (2012)

Overview:

- Uses FSW to physically bond copper, silver, brass plates without melting

- Capable of producing patterns through solid-state shear flow

- Promising for high-efficiency, scalable production

Significance:

Represents an innovative technique for achieving stable bonding and pattern generation using modern industrial processes, independent of traditional methods.

4. Nanostructure Analysis of Bonding Interfaces Using SEM and XPS — Wu & Yamaguchi

Paper (tentative title):

Characterization of Intermetallic Formation in Mokume Gane Copper–Silver–Gold Lamination (2022)

Overview:

- Analyzes interfacial reaction layers (e.g., TiCu₂) formed after diffusion bonding

- Compares structural differences between patterned and non-patterned areas

- Interprets Mokume Gane’s “aesthetic heterogeneity” in terms of metallurgical asymmetry

Significance:

Pioneering research clarifying how the layered structures that create visual beauty are formed and stabilized at the nanoscale.

5. Reproducing Mokume Patterns via 3D Printing (SLM) and CAD — Schmidt et al.

Paper:

Design and Production of Mokume Gane Patterned Jewelry Using Additive Manufacturing (2021)

Overview:

- Generates layered patterns digitally using CAD → builds metal objects via SLM (Selective Laser Melting)

- Allows high design freedom and mass production

- Aims to reinterpret Mokume Gane as a “modern industrial material with traditional aesthetics”

Significance:

A cutting-edge attempt to replace handcrafted patterns with a new paradigm focused on efficiency and scalability.

6. Challenges and Future Directions — Toward Hybrid Methodologies

| Challenge | Content |

|---|---|

| Color Reproduction | Integration with traditional surface treatments like niiro remains unresolved |

| Integrated Technologies | Need for hybridizing vacuum furnaces, FSW, additive manufacturing (AM) |

| Modeling | Use of AI and FEM for pattern prediction and process design |

| Data Development | Creation of international databases for lamination conditions and pattern design |

→ The path forward lies in fusion research that balances traditional beauty with modern scientific precision.

Conclusion

The academic papers introduced here all aim to “reinterpret Mokume Gane through the lens of science and improve reproducibility and scalability.” We are now witnessing a powerful trend that bridges the gap between traditional craftsmanship and modern technology through scientific and engineering approaches.

This article aspires to serve as a guidepost to the forefront of Mokume Gane research—for both scientists and artisans alike.

References

(As in the original Japanese): Asahi Shimbun; Jewelry Seasons Nos. 198–199; The Transmission of the Techniques of Mokume Gane; Metal Jewelry Craft; Mokume Gane Jewelry Handbooks (Ian Ferguson); Mokume Gane – A Comprehensive Study (Steve Midgett); Theorie und Praxis der japanischen Metallverbindungen (Steve Midgett)